In the realm of business equipment, particularly industrial shredders, the goal is longevity rather than immortality. You’ve invested your hard-earned money in an industrial shredder for your business, and naturally, you want it to stand the test of time. Here are seven straightforward tips to help ensure your industrial shredder keeps running efficiently.

1. Clean it Regularly

Dust buildup on the cutters leads to paper jams, hampering your shredder’s efficiency. Follow these steps for effective cleaning:

- Disconnect power.

- Refer to the user guide to access the blades.

- Use a brush to clean the cutters.

- Gently remove jammed paper.

- Always exercise caution around sharp blades.

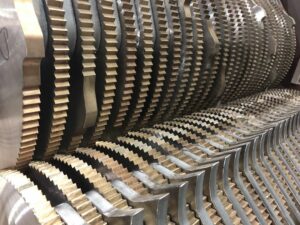

2. Lubricate Moving Parts

Like any machinery with moving components, regular lubrication is crucial for optimal performance. This helps prevent damage, overheating, and ensures a quieter and smoother operation. Consult the user manual for the recommended lubrication method(s).

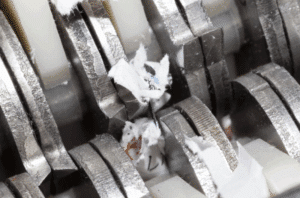

3. Adhere to Capacity Limits

Resist the urge to overstuff your shredder to expedite the process. Operating beyond its maximum capacity can result in jamming and damage to the cutter cylinders. This not only prolongs the job but also causes excessive wear on the motors, shortening the lifetime of your shredder.

4. Keep Shredded Material Moving

Prevent paper shreds from causing jams and dust from sticking to the cutters by using a conveyor to move shredded material away from the blades an into a paper baler. For maximum efficiency, consider a complete shredding system.

5. Follow Material Guidelines

While your industrial shredder may be powerful enough to cut through various materials, it’s vital to stick to approved materials outlined in the user manual. Shredding unauthorized materials can permanently damage the cutters. Additionally, check paper capacity and remove items like fasteners, stickers, and labels that could gum up the blades.

6. Allow for Cooling Time

Just like us, shredders need time to cool down after reaching their maximum run time. Consult your user manual to determine the required cooling-off period. Allowing for proper cooldown time extends the lifetime of your industrial shredder. Remember to turn it off when not in use to prevent overheating.

7. Schedule Regular Maintenance

Keep your shredder in tip-top shape by scheduling regular maintenance. Identifying and addressing worn or damaged parts helps prevent breakdowns and minimizes downtime. Only qualified personnel should conduct maintenance, following the manufacturer’s instruction manual.

At Allegheny Shredders, we understand the importance of maintaining industrial shredders. Our products are built to last, and we offer comprehensive services, including maintenance and parts replacement. To find the right industrial shredder for your company, call us at 724-468-4300 or complete the form on this page.

Contact Us

"*" indicates required fields

-

Popular Posts

-

Helpful Resources