Daily Maintenance Essentials

The foundation of long-term shredder reliability starts with daily attention to basics:

- Clear the cutting chamber of debris before starting and after finishing operations

- Listen for unusual sounds that might indicate mechanical issues

- Check oil levels and lubrication points

- Inspect the emergency stop system and safety features

- Clean the area around the auto-feed system if equipped

Weekly Inspection Points

Dedicate time each week for more thorough maintenance:

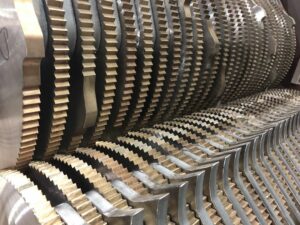

- Examine cutting blades for wear patterns or damage

- Check belt tensions and alignments

- Inspect electrical connections for any signs of wear

- Clean cooling vents and filters

- Review conveyor systems for proper operation

Monthly Maintenance Musts

Once a month, perform these critical tasks:

- Conduct thorough lubrication of all specified points

- Check and tighten all mounting bolts

- Inspect hydraulic systems for leaks or wear

- Clean and examine electrical cabinets

- Test all safety interlocks and emergency systems

Professional Service Intervals

Even with excellent in-house maintenance, professional service is essential. Our expert technical support team recommends scheduling professional maintenance:

- Every 6 months for high-volume operations

- Annually for standard-use equipment

- Immediately if you notice performance changes

- After any significant paper jams or mechanical issues

Extending Equipment Life

To maximize your shredder’s lifespan:

- Never exceed the rated capacity

- Train operators properly on machine operation

- Keep detailed maintenance logs

- Use only manufacturer-recommended parts and supplies

- Address minor issues before they become major problems

Remember, proper maintenance isn’t just about preventing breakdowns – it’s about protecting your investment. Whether you’re operating a J-Series office shredder or a complete shredding system, following these maintenance protocols can help ensure years of reliable service.

Need expert guidance on maintaining your industrial shredder? Contact Allegheny Shredders today to learn more about our comprehensive maintenance programs and technical support services.

Contact us now to discuss your equipment maintenance needs or schedule a professional service visit.

Contact Us

"*" indicates required fields

-

Popular Posts

-

Helpful Resources