1. Neglecting Research on Shredders

Anyone looking to purchase an industrial shredder would prefer an efficient and cost-effective, sturdy and reliable high-volume shredder. However, neglecting to research the key factors is a common mistake. It’s crucial to consider:

- The manufacturer’s history and track record

- The models and options they offer

- Whether their equipment is American-made

- The quality of their customer support, parts and service, and warranty

Start by exploring informational resources, such as this brochure about Information Destruction Equipment, to make an informed decision.

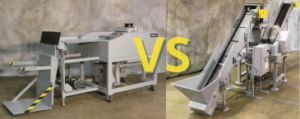

2. Incorrect Size and Type Selection

Choosing the right industrial shredder involves more than just considering its size. It’s essential to match the shredder’s capacity, feed opening, size, disposal method, and optional equipment to your specific needs. Whether it’s strip-cut or cross-shred, gravity-fed or conveyor-fed, understanding your requirements is vital. Consult with a professional industrial shredder manufacturer to ensure that you select the right type and size for your business.

3. Ensuring Quality and Reliability

Investing in an industrial shredder necessitates a focus on quality and reliability. To determine the durability of the equipment, directly research the manufacturer or vendor, inspecting the components and materials used. Watch online demonstrations of the shredder in action or, ideally, observe it operating in person. Does the manufacturer have a showroom you can visit and watch the shredders in action? Finally, look for reviews from other users to gain insight into the purchase and operating experience.

4. Adequate Space Consideration

Ensure that the purchased shredder aligns with your available space. Evaluate not only the shredder itself but also the entry and exit areas, along with the operational space required around the equipment. This foresight guarantees optimal efficiency within the available space.

5. Planning for Future Growth

Anticipate your company’s growth over the next few years and tailor your shredder purchase to accommodate these expectations. Don’t just buy for the present; plan for the next five years to ensure your shredding needs evolve seamlessly with your company.

Allegheny Shredders, serving as both manufacturer and vendor, offers comprehensive service from purchase to setup, operation, and maintenance of your industrial shredder. For expert guidance in selecting the right equipment, contact us at 724-468-4300 or complete the form on this page.

Contact Us

"*" indicates required fields

-

Popular Posts

-

Helpful Resources