If you find yourself in the market for an industrial-sized shredder, you may hear one recommendation for cross-cut shredders and another recommendation for particle-cut shredders. At first glance, you might wonder, “What’s the difference?” It’s a valid question, especially when your primary concern is to choose equipment that perfectly aligns with your shredding needs. In this article, we will delve deeper into the benefits of each option to help you make an informed decision.

Since the main criteria for your choice will be to get the equipment that best matches your shredding needs, let’s look at the benefits of each option so you can decide which would work best for you.

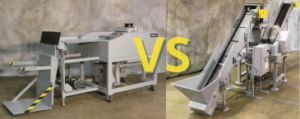

Cross-Cut Shredder

Cross-cut shredding is often regarded as the gold standard when it comes to shredding security, particularly for those dealing with high volumes of sensitive documents. Here are some key advantages of cross-cut shredders:

- Enhanced Security: For organizations that prioritize security, cross-cut shredding is the most secure method of destruction.

- Small Shred Size: Cross-cut shredders achieve an exceptionally small shred size by employing a two-stage shred process where two shredding mechanisms are positioned perpendicular to each other. This results in confetti-sized paper remnants, making it nearly impossible for anyone to reconstruct the original content.

- Increased Throughput: One of the notable advantages of cross-cut shredders is their ability to increase throughput volume by up to 50%. This means you can process a larger volume of documents in less time, improving overall efficiency.

- Efficiency and Quiet Operation: Cross-cut shredders are known for their efficiency and quiet operation. They make minimal noise and dust, creating a more pleasant working environment.

- Easy Installation: Integrating a pre-shredder in front of your existing industrial shredder is a straightforward process. This allows you to enhance the shredding capabilities of your current equipment without significant modifications.

Particle-Cut Shredder

On the other hand, particle-cut shredders offer their own set of advantages, particularly for those dealing with large volumes of material. Here’s what you need to know about particle-cut shredders:

- Shearing Process: Particle-cut shredders use a shearing process to create shorter strips than traditional slitter-type industrial shredders. This process allows for the efficient destruction of high volumes of paper, cardboard, or plastic with minimal labor.

- Bulk Feeding: These shredders are capable of bulk feeding large volumes of material, making them ideal for organizations that need to process substantial amounts of documents quickly. This “dump and run” capability saves time and effort.

- Recycling Benefits: The output from particle-cut shredders can often be fed directly to a baler. This is advantageous for organizations looking to profit from recycling shredded materials, as the compacted output is easier to manage and transport.

In the end, choosing between a cross-cut shredder and a particle-cut shredder largely depends on your specific requirements. Cross-cut shredders excel in providing maximum security and efficiency for sensitive documents, while particle-cut shredders are ideal for high-volume shredding with an eye on recycling profits.

Allegheny Shredders is your trusted partner for quality, efficient, and effective industrial shredding equipment. We also offer optional equipment and add-on items to optimize your shredding process further. To inquire about industrial shredders, we welcome you to call us at 724-468-4300 or complete the form on this page. We’ll help design a completely customized shredding system to maximize your shredding productivity and keep your labor costs down.

Contact Us

"*" indicates required fields

-

Popular Posts

-

Helpful Resources